Lower cost of ownership

Price

By manufacturing every RVM in our own advanced facility, we control quality and costs at every step. This allows us to deliver the latest technology at a highly competitive price, ensuring you get maximum value for your investment.

Compactor

Our patented compactor features interchangeable blades, so after years of use, it can be quickly refreshed onsite. This unique design extends the machine’s lifespan, reduces costly downtime, and keeps maintenance expenses low.

Reliability

Every component in a Recyclever RVM is industrial-grade, built for long-term, high-volume use. This ensures consistent, trouble-free operation and minimal service calls—delivering real savings over the life of your machine.

Media Screen

Turn cost into opportunity: our high-definition media screen lets you stream targeted advertising and brand content. Generate new revenue streams that can offset, or even surpass, the total cost of ownership.

Space saving, with large capacity

Depth

With a footprint depth of just 90cm, Recyclever RVMs are designed to fit seamlessly into even the most space-constrained retail environments—maximising placement flexibility without sacrificing performance.

Width

Choose from 67cm, 100cm, or 120cm widths to match your available space and expected container volume. Our modular sizing ensures you get the perfect balance of capacity and compactness for your location.

Compaction

Each model features adjustable, material-specific compaction settings for PET, aluminium, and glass. This optimised compaction maximises storage efficiency, allowing more containers per square metre and reducing emptying frequency.

Large Capacity

Despite their compact footprint, all Recyclever RVMs are engineered to store a high volume of containers. You benefit from fewer collections, less staff intervention, and uninterrupted service—even in high-traffic locations.

Guaranteed success of the return initiative

Any container type

Accepts PET bottles, aluminium cans, and glass containers—ensuring your return initiative is accessible to all users and maximises participation, regardless of container preference.

Easy to use

Designed for intuitive operation, Recyclever RVMs make the return process simple and satisfying. Clear instructions and user-friendly interfaces mean everyone can participate with confidence.

Fast

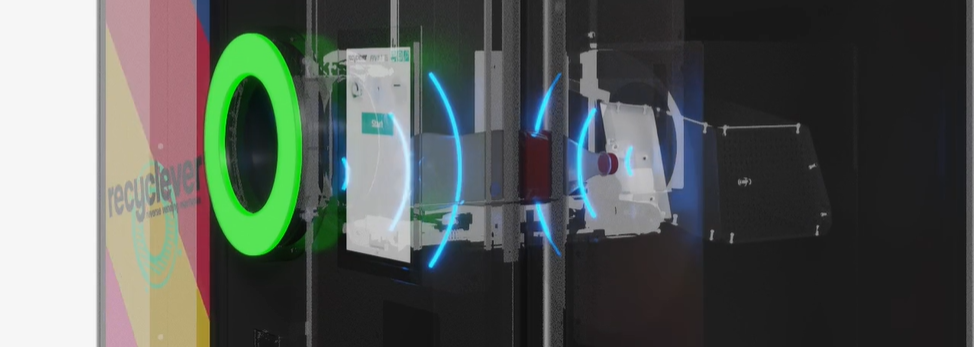

Our advanced 360° scanner and seamless validation process deliver rapid, accurate returns. Customers enjoy minimal wait times, keeping queues short and satisfaction high.

No Fraud

State-of-the-art anti-fraud technology ensures only eligible containers are accepted. This protects the integrity of your deposit system and guarantees that every return is legitimate.

Happy, returning users

Smooth processing

Fast, seamless return sessions ensure users complete their recycling quickly and effortlessly—encouraging them to return again and again.

Intuitive

The interface is designed for clarity and ease, so every step feels natural and obvious—even for first-time users.

Nice

A clean, modern design and engaging user experience make recycling enjoyable, leaving a positive impression every time.

Interactive

The responsive touch screen and interactive features invite users to engage—whether redeeming rewards, making donations, or exploring new promotions

Engaged customers

Media Screen

Leverage users’ dwell time with a high-definition media screen—deliver targeted promotions, brand messages, and integrate voucher issuance to boost engagement and drive in-store activity.

Touch Screen

Empower customers with interactive options: make donations, scan codes, or select rewards directly from the intuitive touch screen—enhancing both engagement and satisfaction.

Printed Vouchers

Seamlessly connect recycling with loyalty programmes and apps: customers can scan a code on the screen to receive printed vouchers, making reward redemption fast and convenient.

Apps Integration

Effortlessly link digital experiences—customers can present their in-app code to the NFC/code reader or scan the on-screen code, enabling smooth integration with loyalty apps and personalised offers.

Safety, our top priority

Separator

A robust physical barrier ensures the compactor is completely inaccessible from the outside, providing unmatched user safety at all times.

Compactor

Strategically positioned below the separator, the compactor remains unreachable—even if safety sensors fail—guaranteeing continuous protection during operation.

Industrial Grade

All components are industrial-grade, engineered for durability and reliability, minimising the risk of failure and ensuring safe, long-term performance.

Safety Sensors

Advanced magnetic safety sensors automatically cut power to the compactor whenever the machine is opened, delivering an extra layer of operational safety.

Total Fleet Control

RecyHub Portal

Gain complete, fingertip control over your entire RVM fleet with the RecyHub portal—manage, monitor, and optimise every machine from a single, intuitive dashboard.

Telemetry

Access real-time information and live updates from every RVM in your network, enabling instant visibility into status, performance, and operational health.

Preventative Maintenance

Leverage powerful data analytics to predict and schedule preventative maintenance—reducing downtime, extending machine life, and ensuring continuous service.

Data, to and from

Each RVM streams live data to the portal and receives updates remotely—such as new container databases or voucher changes—keeping your fleet always current and compliant.

API Integrations Readiness

APIs with DMO

Direct API integration gives scheme operators real-time access to return events and detailed statistics, ensuring transparent reporting and regulatory compliance.

APIs for Apps

Seamless app connectivity—two-way APIs enable apps to interact with the machine, creating smooth, engaging user experiences and personalised journeys.

APIs & POS systems

Secure APIs connect RVMs with POS systems, enabling instant issuance and redemption of one-time vouchers—streamlining the reward process for both retailers and customers.

Multi-system integration

Recyclever’s API-ready platform supports integration with multiple systems, empowering you to engage consumers across channels and future-proof your operations.

Reverse Vending Machines

Features

Speed Of Processing

Exceeding 12 containers per minute, to make deposit return scheme a success.

Capacity

Recyclever RVMs hold large capacitiy of compacted containers aiming at one emptying per day.

Dimensions

Stand alone design and compact dimensions to ease deployment.

Green Footprint

Low power consumption both in stand-by mode and during operation. Enhancing the circular economy with the lowest pollution!

Separation

All Recyclever RVMs come with separation: PET from aluminium, or PET and aluminium from glass.

Voucher System

Issue redeem and rewards via printed vouchers or mobile applications.

DDA

With a entry point height of 135cm / 4'5", a touch screen and printer at comfortable heights, our machines comply to the wider public use.

IP Rating

Our reverse vending machines are IP20 rated, allowing them to be used indoors or outside under a canopy.

Anti-Fraud

The most advanced combination of technologies to reduce fraud. Silhouette shape, dimensions, materials, movement, weight.

Revenue Opportunity

Use the hi-definition media screen to stream content. Involve suppliers and partners to generate revenue via advertising.

Easy Maintenance

Our unique design allows the simple replacement of parts. Our designs allow for simple maintenance and servicing.

Telemetry

Recyhub, our comprehensive reporting and analysis portal, reports live insights into customer behaviour and transaction data.

Key Team

Andy Magrini, MD

Andrea (Andy) is the managing director of

Recyclever. With a passion for the environment, Andy was instrumental in bringing Recyclever to market. He continues to play a key role in driving its evolution and success. See Andy's Linkedin Profile Here

Chris Wood, Head of Operations

Chris heads up the Recyclever team, driving development and innovation. With an extensive background in retail operations at a large supermarket chain in the UK, he manages the stratetigic growth of Recyclever. See Chris' Linkedin Profile Here.

Mission

Recyclever mission is to accelerate the transition to a circular economy.

Legislation

The European Directive 2019/0904 requires a recycling rate of 90% by 2029. Member states can achieve this by adopting Deposit Return Schemes.

Deposit Return Scheme

In a DRS consumers buying drinks pay a deposit on the containers. The deposit is redeemed upon the return of the empty container.

Reverse Vending Machine

An RVM is an automated return point for empty drinks containers. It selectively accepts empty containers, prevents fraud and issues redeemable vouchers.

Frequently Asked Questions (FAQ)

Q1: What is a Reverse Vending Machine (RVM)?

A1: A Reverse Vending Machine is a device that accepts used beverage containers and returns a reward to the user, typically in the form of a voucher or deposit refund. These machines are designed to encourage recycling by making it easy and rewarding for consumers to return their empty containers.

Q2: How do Recyclever RVMs support the circular economy?

A2: Recyclever RVMs facilitate the collection and recycling of beverage containers, which helps to reduce waste and promote the reuse of materials. This supports the transition to a circular economy by ensuring that resources are kept in use for as long as possible.

Q3: What types of containers can Recyclever RVMs process?

A3: Our machines are capable of processing PET bottles, aluminum cans, and glass containers. They use advanced shape recognition technology to accurately identify and sort these materials.

Q4: Can Recyclever RVMs be customized for specific needs?

A4: Yes, Recyclever RVMs can be customized to meet specific requirements, such as accepting only certain types of containers or integrating with loyalty programs. We offer bespoke branding and configuration options to suit different business needs.

Q5: What are the benefits of installing a Recyclever RVM for businesses?

A5: Businesses can benefit from increased customer footfall, enhanced green credentials, and additional revenue streams through advertising on the machine's media screens. RVMs also help reduce waste management costs by compacting containers.

Q6: How does the anti-fraud technology in Recyclever RVMs work?

A6: Our RVMs use a combination of computer vision and authentication sensors to detect and prevent fraudulent activities. The system can identify and reject containers that do not meet the criteria for deposit return.

Q7: What is the installation process for a Recyclever RVM?

A7: Installing a Recyclever RVM is straightforward. We offer an installation service, or you can opt to set up the machine yourself by following the on-screen instructions for calibration and connection.

Q8: How does Recyclever ensure the machines are easy to maintain?

A8: Our machines are designed for easy maintenance with features like simple part replacement and comprehensive service manuals. Regular maintenance checks are recommended to ensure optimal performance.

Q9: Can Recyclever RVMs generate revenue through advertising?

A9: Yes, our RVMs are equipped with high-definition screens that can display advertisements, promotional videos, and other content. This provides an opportunity for businesses to generate additional revenue.

Q10: Where are Recyclever RVMs manufactured?

A10: Recyclever RVMs are manufactured in the UK, ensuring high-quality production standards and reducing the carbon footprint associated with shipping.

Q11: How can I track the performance of my Recyclever RVM?

A11: Recyclever RVMs come with a built-in analytics platform that allows you to monitor performance metrics such as the number of containers collected, machine uptime, and user engagement. This data can be accessed remotely via a secure online portal.

Q12: Are Recyclever RVMs environmentally friendly?

A12: Yes, Recyclever RVMs are designed with sustainability in mind. They help reduce waste by promoting recycling and are built using energy-efficient components to minimize their environmental impact.

Q13: What support does Recyclever offer after installation?

A13: We provide comprehensive support services, including technical assistance, maintenance, and software updates. Our customer service team is available to help with any issues or questions you may have.

Q14: Can Recyclever RVMs be used in outdoor locations?

A14: Yes, our RVMs are designed to withstand various weather conditions and can be installed both indoors and outdoors. They are equipped with weatherproof features to ensure reliable operation in different environments.

Q15: How do Recyclever RVMs contribute to corporate social responsibility (CSR) goals?

A15: By installing Recyclever RVMs, businesses can demonstrate their commitment to sustainability and environmental stewardship. This can enhance their CSR profile and appeal to eco-conscious consumers.

Q16: What payment options are available for users of Recyclever RVMs?

A16: Users can receive their deposit refunds through various methods, including cash vouchers, digital credits, or donations to charity. This flexibility encourages more people to participate in recycling.

Q17: How do Recyclever RVMs handle different container sizes?

A17: Our machines are equipped with adjustable mechanisms and sensors that can accommodate a wide range of container sizes, ensuring efficient processing and sorting.

Q18: Can Recyclever RVMs be integrated with existing recycling programs?

A18: Yes, Recyclever RVMs can be seamlessly integrated into existing recycling initiatives, enhancing their effectiveness and reach. We work closely with partners to ensure compatibility and success.

Q19: What security features are included in Recyclever RVMs?

A19: Our RVMs include robust security features such as tamper-proof designs, secure data transmission, and real-time monitoring to prevent unauthorized access and ensure data integrity.

Q20: How can I learn more about purchasing a Recyclever RVM?

A20: For more information on purchasing a Recyclever RVM, please contact our sales team through the contact form on our website or call our customer service hotline. We are happy to provide detailed information and assist with your purchase.