RECYCLEVER REVERSE VENDING MACHINE STANDARD FEATURES

REVERSE VENDING MACHINES MODELS

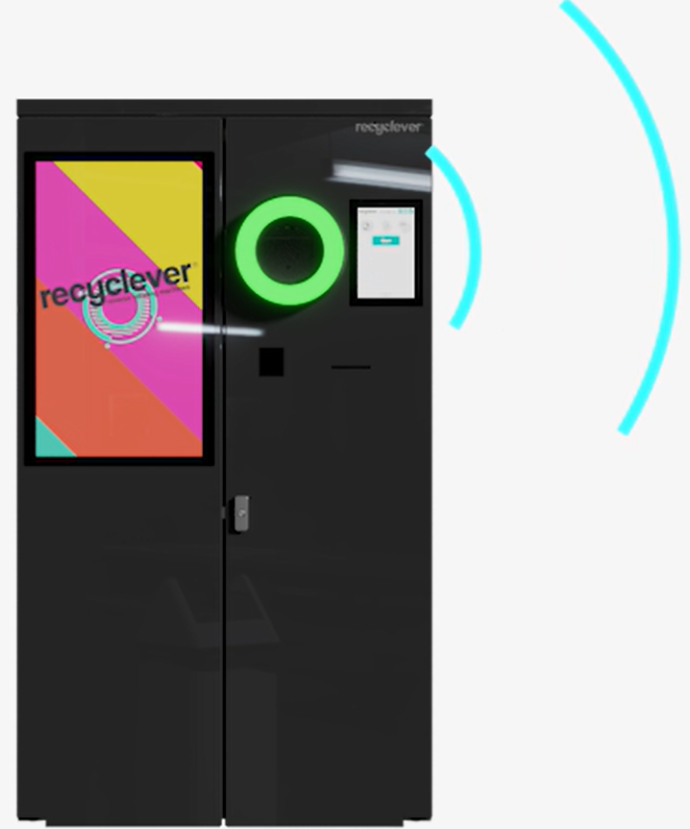

RVM5 - 1000

RVM5-1000 REVERSE VENDING MACHINE

The RVM5-1000 is a reverse vending machine designed for deposit return schemes (DRS) and AI-based recycling. It processes 12+ containers per minute, handling PET bottles and aluminum cans. With smart fraud detection, sorting, and remote monitoring, it operates efficiently in retail and public locations, promoting sustainable waste management through incentivized recycling programs.

Ultrafast Barcode Scanning

The 360° barcode scanner allows a rotation-less processing of containers.

Multi layer validation

We prevent fraud by validating a container by checking the material, the weight, the dimensions, the movement and the silhouette.

Materials

Sorting

PET, Aluminium, Glass are separated into two separate bags, to optimise the recycling process.

Innovative

Compactor

Containers are compacted to increase the bin's capacity and avoid containers being processed a second time.

RVM5 - 800

RVM5-800 - REVERSE VENDING MACHINE

The RVM5-670 is a compact reverse vending machine, ideal for locations with limited space. It processes 12+ containers per minute, handling PET bottles and aluminum cans. Lacking a media screen, it is more cost-effective, while retaining anti-fraud features, smart sorting, and remote monitoring, making it an affordable, high-efficiency recycling solution.

The most compact RVM in the market

The 670 is the smaller Reverse Vending Machine in the market and it still has all the technology, material separation and compaction.

Fraud prevention technology

Despite its incredibly compact dimensions, the RVM5-670 still includes all the technology to prevent fraud.

Multimaterial and separation

In just 67cm of wdith, the RVM5-670 offers material separation and compaction as standard. Including glass!

Perfect Compaction

Recyclever's dual chamber compactor delivers the best compaction rates for PET, aluminium and glass!

RVM5 - 1200

RVM5-1200 - REVERSE VENDING MACHINE

The RVM5-1200 is a high-capacity reverse vending machine, processing up to 1,600 containers with PET and aluminum sorting. With expanded storage, it is ideal for high-traffic locations. Featuring anti-fraud technology, remote monitoring, and smart sorting, it maximizes efficiency and sustainability in deposit return schemes (DRS) and larger-scale recycling programs.

Large Capacity

Thanks to its width of 120cm, the RVM5-1200 offers large storage capacity well in excess of 1,500 containers for busier supermarkets.

Validation Technology

We prevent fraud by validating a container by checking the material, the weight, the dimensions, the movement and the silhouette.

Plastic, Aluminium and Glass

PET, Aluminium, Glass are separated into two separate bags, to optimise the recycling process.

Compactor with longer life

Recyclever's patent make it possible to give a new life to a compactor thanks to a simple blades replacement.

Sorting

Choose the materials your Reverse Vending Machine will collect and how they are organised.

PET + ALU Separated

PET + ALU Combined

GLASS Break

The Digital Side

From your own collection system powered by our AI-Mode to a fully DRS-compliant configuration.

Barcode Database

Accept any container or upload the data of those to be accepted.

Shape Programming

Teach our AI shape recognition to accept your containers.

Voucher Production

Provide your customers with printed or digital vouchers.

Media Power

Use the Hi-definition multimedia screen to interact with your consumers and generate revenue.

Touch Screen

Adopt our default interface or configure your own.

Media Screen

Prepare content or engage with your suppliers.

Content Management

Use our CMS or integrate with third party media platforms.

Patented Conveyor

The unique conveyor is easily removable to be cleaned and washed.

Patented Separator

A unique device separating the materials and guaranteeing the maximum safety of use.

Patented Compactor

Industry leading compactor featuring unique compacting rates and maintenance capabilities.

TECHNOLOGY FOR DEPOSIT RETURN SCHEME

Rotationless Processing

The Ultrafast 360° scanner delivers the easiest customer experience by picking any EAN barcode instantly.

The ring has coloured light to interact with the customer: green for next container, red for wait and others for store operators and maintenance teams.

Fraud Prevention

The highest degree of technology to prevent fraud. The RVM checks the barcode, PET material, metal material, weight, movement, sizes and silhouette: the checks happen at lightning fast speed and in case any check fails, the container is returned and the session doesn't trigger a credit or refund.

Removable Conveyor

The single bed throughed conveyor is removable for easy cleaning.

Materials get always Separated

All Recyclever RVMs feature a patented separator. This can be programmed to sort materials to the client's preference: PET on one side and Metal on the other, or PET & Metal co-mingled in one side and Glass on the other.

Renewable Compactor

The dual chamber patented compactor has unique compacting plates which are easily replaceable in a few minutes to give a whole new life to the compactor.

The plates are optimised in design for PET bottles, aluminium containers and glass bottles, which are forced break to avoid fraud and ease onward recycling.

RecyHub Telemetry Portal

Recyclever RVM's are connected to the RecyHub portal. They receive up to date parameters on how they should work, like updated drinks databases. They then feed data on every event.

RecyHub comes with APIs capabilities to integrated with DMO's and retailers' POS systems.

CUSTOMER INTERACTION WITH THE RVM

Media Screen

The un-breakable screen to generate revenue.

Involve your suppliers and FMCG brands in the drinks containers collection initiative. Reverse Vending Machines are high-interaction points for the customer and this media screen will grab attention. Integrate it with up-selling initiatives integrated in the voucher!

Touch Screen

Allows the user to begin and end sessions. With a PIN code, store staff and maintenance team get their specific access to the machine.

The screen can also display codes, received via the RecyHub APIs, to be scanned from their loyalty APP.

NFC, QR code scanner

The scanner allows for consumer APPs integration: whether NFC or a barcode on the screen, the RVM can attach this data to the returns session result.

Printer

The presenter printer issues vouchers to the customer when their session is finished. The printer is connected to RecyHub and can issue logic vouchers programmed via the APIs.